Cigre Australia

empowering

networking

global know-how

WG B2.69 Coatings for Power Network Equipment Part 2

There have been numerous advancements made in the last decade regarding surface engineering techniques and surface coatings which improve reliability and reduce capital costs. This is the second of two articles on this topic. The first related to TB 837: Coating for improvement of electrical performance of outdoor insulators under pollution conditions and this was published in the December 2021 In the Loop. The second, TB 838: Coatings for protecting overhead power networks against icing, corona noise, corrosion and reducing their visual impact, is discussed here. The Australian member of this working group was Francis Lirios.

Technical Brochure 838 starts with a discussion on the advancements made over the past decade on surface preparation and various coatings used on overhead powerlines, as well as the opportunities this provides for improved asset performance, including lessening visual impact.

The main power network assets considered in the Technical Brochure are insulators, conductors, ground wires, and transmission line structures. The coatings that were investigated are those that provide anti-icing on conductors, ground wire, insulators; anti-noise on conductors and fittings; anti-corrosion on metallic parts; and camouflage regarding the general appearance of the line against its environment.

The Working Group determined that passive anti-icing coatings were still lacking in the commercial world, while active coatings such as those based on electrolysis of ice and the injection of a pulsed current into a conductor coating on conductors or ground wires are either inefficient or impractical. Further R &D is required for an effective solution on melting wet snow using ferromagnetic coating.

For coatings aimed to mitigate or remove audible noise (anti-noise coatings) caused by corona discharge near the conductors, insulators and fittings, the Working Group determined that in addition to sandblasting or bead blasting of the conductor surfaces, the application of hydrophilic coatings on these assets can, in certain cases, give a better result than bead-blasting. This particular treatment is good for existing lines emitting audible noise, as well as new lines.

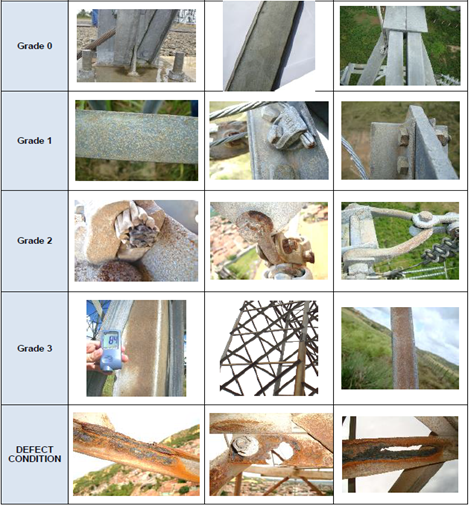

For anti-corrosion coatings, the Technical Brochure presented various methodologies utilised by companies, asset managers, asset owners, etc. in assessing the corrosion degradation on power network assets located in coastal and/or industrial areas. It also presented the various techniques used to prevent and/or mitigate the effects of corrosion on these assets.

The effectiveness and durability of the corrosion protection system is dependent on the correct timing of the intervention, as well as using the correct coating system for any particular application, ie. environmental parameters and equipment to be protected. Field testing is seen as an effective way to assess the performance of the system, albeit the time element is challenging. Lastly, further R&D is required to develop more effective and durable coatings for use in highly corrosive environments.

For coatings used to conceal or lessen the visual impact of power assets (ie camouflage coatings), several manufacturers have developed their own products since the 1980’s. This method of coating is done during the production phase of steel elements using a brush technique, but more recently powder coatings are being utilised. For conductors and ground wires, the main technique is the application of varnishes and/or coatings by an electrochemical process. For insulators, the current technique is to use RTV silicone coating using a wire brush technique, either on existing strings or in the factory.

The use of camouflage coatings should be considered in the planning phase as this adds to the material cost. Also, what can be hidden during one part of the year may become less effective on a different season, especially when the background of the tower changes.

The Technical Brochure is available via e-cigre - free for members and 290€ for non-members.

Photos above: Photographic patterns summary table of the corrosion degrees in structures (photo credit, Table 4.4, CIGRE TB 838)